Futorque® WIP & SmartClean

Contained production OEB 3-5, fully washable

Single layer tablets R&D and small scale production

max. 129,600 tabs/h

EU/IPT B, D etc.

Scale-Up

18,5" BECKHOFF MultiTouch display

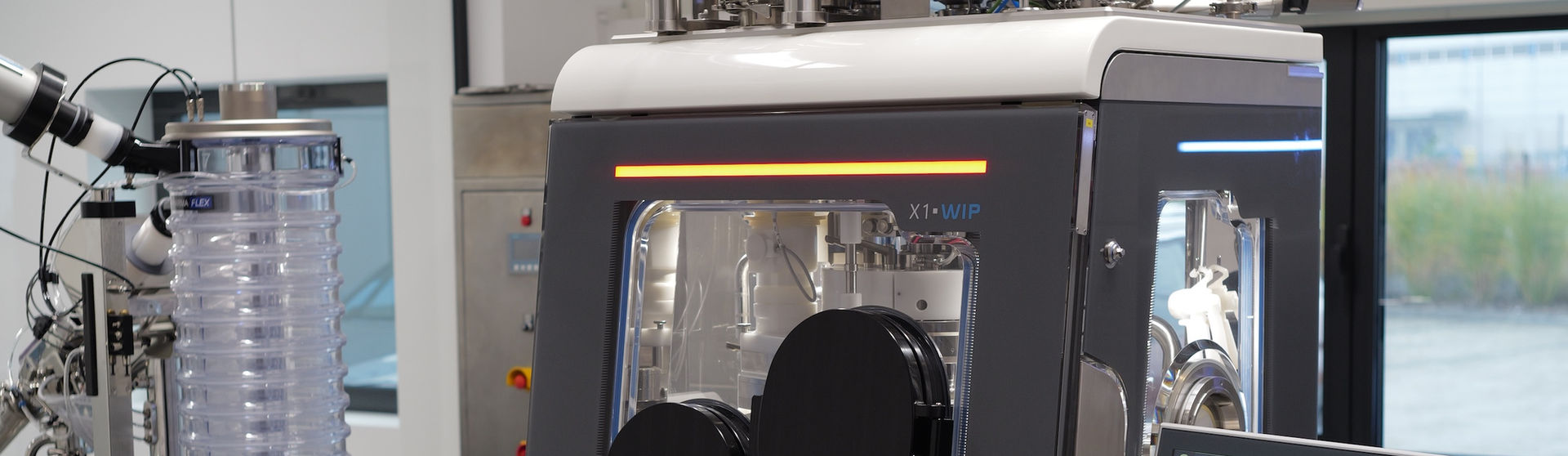

The cutting-edge contained hybrid tablet press for R&D and production

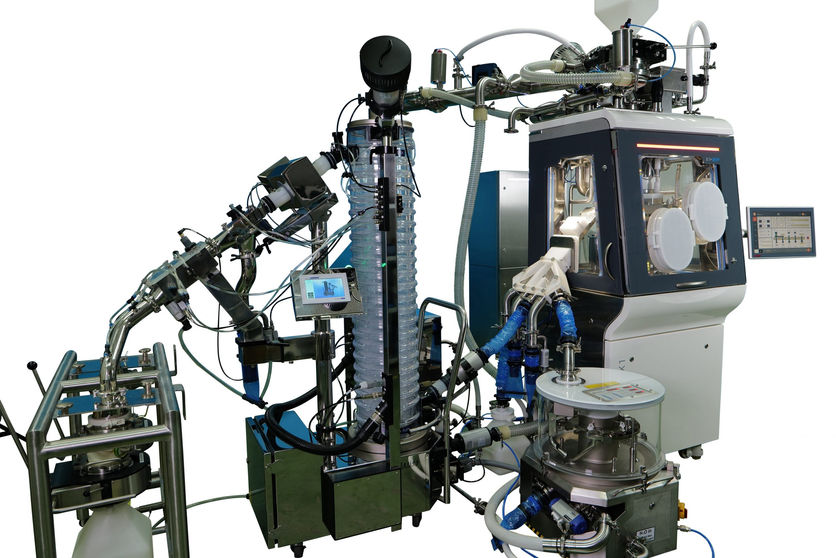

The Futorque® is the most compact hybrid tablet press available, requiring only 20 m² for the entire line, including the WIP-capable Pharmatec tablet deduster, CEIA metal detector, and tablet container.

This space-saving design allows for easy installation in tight spaces, potentially reducing renovation or expansion costs.

As a versatile hybrid tablet press, the Futorque® seamlessly transitions between R&D and production, achieving an impressive output of up to 129,600 tablets per hour. The unique "FlexAdapt" turret system accommodates any standard tooling format without exchanging the turret, offering significant cost savings.

Key features:

-

Fully automated in-process control (IPC) system

-

Fully washable Krämer-Elektronik tablet tester

-

5-channel tablet discharge system for various sampling options

-

Available in OEB 3 "SmartClean" and OEB 4/5 "WIP" versions

-

Intuitive software for easy operation, even for less experienced operators

The Futorque® is ideal for toxic active ingredient mixtures, pushing the boundaries of efficiency and effectiveness in tablet pressing.

Contact us to learn how the Futorque® can revolutionize your pharmaceutical manufacturing process!

Learn more about the contained Futorque® series

About the product

Operation software

CADERA machine design

Unique multi purpose concept for standard pharma and containment applications

Software

Compare our tablet presses

With its Futorque® WIP and SmartClean, kg-pharma is offering a hybrid rotary tablet press with an integrated containment that sets new standards worldwide for R&D and production purposes.

The system performance pays off from the preparation of clinical studies and orphan drugs all the way to medium-sized production batches, since thanks to the use of Futorque® no major production machine has to be stopped and a high tablet output is nevertheless possible

The flagship sets standards in design and intuitive operation. An huge 18.5″ BECKHOFF multitouch display – and a all new control software simplifies usage significantly.

This machine type is outstanding with its state-of-the-art EtherCAT operation and monitoring technology. The best basis for fast data transmission and a multi-compatible industrial standard software

The times when all pharma-machines were built in gray stainless steel have now gone. kg-pharma sets new standards in visual terms as well.

The simple yet elegant “waterfall” front design in white polycarbonate has been combined with sides of stainless steel sheet. For this purpose, the renowned German industrial designer Tom Cadera from Würzburg was given the remit of creating a development for the future

The Futorque® WIP offers, as one of many other technical innovations, a high torque servo drive for maximum force at slow turret speed, often required in R&D. The product name chosen for the range has been coined from a combination of the words “future” and “torque”. The standard turrets B-18 and D-14, the combi-system and the FlexAdapt X-14 system offer a pitch circle of 240 mm.

Can you sense our enthusiasm and would you like to be part of it?

Our sales specialists will draw up the best offer possible, tailored to suit your individual needs. The potential savings and enhanced production options combined with optimized deployment planning cannot fail to convince you in the end.

Find the right tablet press for the needs and requirements of your business.

Gallery

Impressions of the Futorque® WIP OEB 5